The two main parts of the clock.

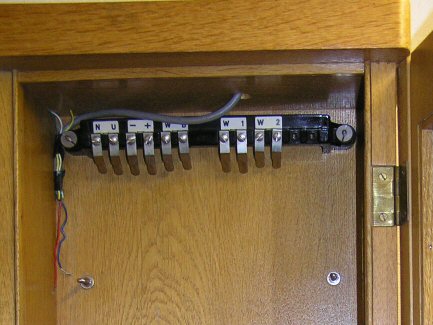

The clock mainly comprises of these two separate units that link together. The black coloured backboard is mounted into the case and is held in quiet simply, but effectively, by two thumb screws.

The top of the backboard has metal springs that then make a pressure contact with the similar springs that can be seen in the top of the case.

This is actually a very effective and reliable system, making removal of the unit very easy.

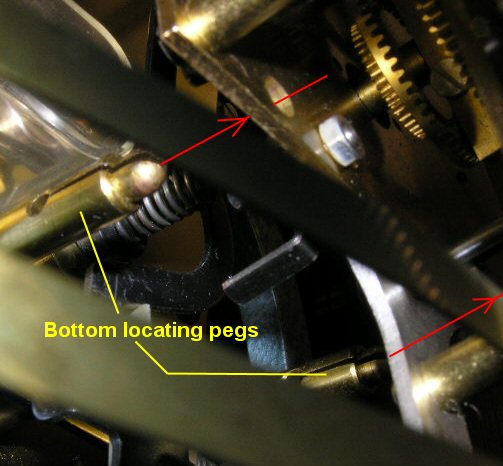

Once the main backboard has been replaced, and the pendulum hung on its suspension spring, the main clock unit is replaced by hanging it onto the two lugs at the top, the bottom is then pushed firmly home.

The bottom part is retained by two split lugs on the backboard that push into two holes that they align with on the main clock mechanism. You can see this in the picture below, the red arrows showing where the split lugs will locate. The mechanism's contacts are like those at the top, except in this case the contacts press against the top of posts that project out of the backboard. These try to resist you pushing the mechanism home to locate it, so sometimes a reasonable effort is required before the spring lugs lock into their respective holes.

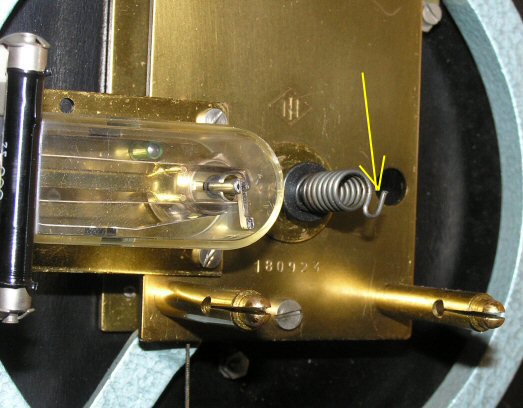

Because of this extra effort, all too often people can cause damage, this is because the spring that is shown below gets bent. This occurs when the spring is in the wrong position with regard to the spindle that it pushes onto. The secret is to make sure that the position of the curled end on the spring (shown arrowed) is 180 degrees out of alignment with the pin it engages with on the clock spindle. This way it ensures that when the 'flywheel' gets a push from the electro-magnet and the spring turns for the first time, it will come into contact with, and latch onto, the pin mentioned earlier.

A similar procedure also needs to adopted for the contact set that sits under the plastic cover. These are opened and closed by a little lever that rotates around once a minute, this giving the pulse to the slave clocks, which on this clock is a simple reversal of DC voltage once a minute. This differs from, and is in fact more reliable than, the "normal" English master clock system of a DC pulse every 30 seconds.

Go to Page 2